Home » vision systems

Articles Tagged with ''vision systems''

Different Machine Vision Network Interface Options

Choosing the right network interface is an important part of developing successful machine vision applications.

March 1, 2017

V&S HEADLINE

Call for Startups Announced for Automate Launch Pad Competition

February 13, 2015

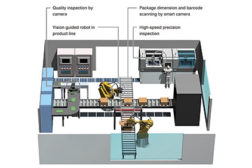

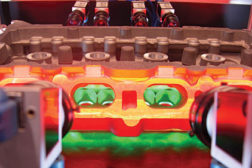

The Dawn of the Smart Factory

INDUSTRIAL SMART CAMERAS ADVANCE AS EMBEDDED VISION SYSTEMS WITH NEW GENERATION PROCESSORS ARE INTRODUCED.

September 11, 2014

Turnkey Machine Vision Systems

Today’s tools can make even the most difficult vision inspections plausible

December 10, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing