Measurement

Coordinate Metrology Society

Skills gaps and shortages create demand for workers and education.

Read More

INDUSTRY HEADLINE

Hexagon Partners with GF Machining Solutions and FANUC America for HxGN LOCAL Event in Huntersville, NC

July 3, 2018

INDUSTRY HEADLINE

Michigan Metrology Announces Short Course to Further the Understanding of Surface Texture and Tribology

July 2, 2018

Improvements in Aluminum Aircraft Components Using X-ray Diffraction Residual Stress Measurements

Residual stresses can be controlled in the manufacturing process to produce a superior product that will last even in harsh environments.

July 1, 2018

Benefits of Multi-Sensor CMMs by Industry

Aerospace, automotive, and medical device OEMs, take note.

June 28, 2018

INDUSTRY HEADLINE

Automation Trends At IMTS 2018: Cobots, Cameras, Careers, Mobile Robots, IIoT, AI And More

June 25, 2018

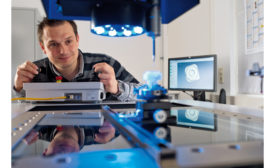

Precision Manufacturing

Leading edge metrology systems help ensure component quality.

June 15, 2018

Using CMMs for Surface Finish Measurement

Advancements in motors and sensors improve CMM surface measurement capabilities.

June 15, 2018

NDT WEB EXCLUSIVE

Eddy Current NDT Equipment Market to Reach $538 Million by 2026

June 8, 2018

Understanding Calibration Reports

Read them—don’t simply check for red flags.

June 8, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing