Measurement

It’s important to know beforehand what the instrument can and cannot do.

Read More

INDUSTRY HEADLINE

VJ Technologies and Datest Partner in West Coast Inspection Services, Showroom and Demonstration Center

October 27, 2017

Accurate and Repeatable Measurement

Using a rotary table on a CMM will improve process efficiency and productivity by reducing setup and process times.

October 24, 2017

It’s the Other Stuff that’s the Problem

Sometimes you have to start looking at the less obvious culprits.

October 24, 2017

INDUSTRY HEADLINE

New Metrology Program at Fullerton College to Integrate Romer Absolute Arms and CMMs from Hexagon Manufacturing Intelligence

October 18, 2017

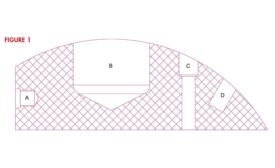

Form Measurement: Making it Easy

Understanding these issues may help you advance your process, or at least, make things less difficult.

October 17, 2017

INDUSTRY HEADLINE

North Star Imaging Opening New Inspection Lab On East Coast

October 9, 2017

Taking Measure

The need to optimize throughput is a common denominator across industry lines.

October 3, 2017

Depth Measurement Challenges

Let’s look at some of the part and gage features that may impede accurate depth measurement.

October 3, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing