Test & Inspection

INDUSTRY HEADLINE

ASTM International to Host November Symposium on Additive Manufactured Parts

August 23, 2018

NDT HEADLINE

Tour de France to Test Bicycles for Technical Fraud Using VJ Technologies' Mobile X-ray Inspection Unit

August 22, 2018

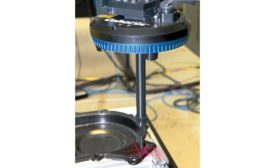

Where to Start with Ultrasonic Thickness Gaging

There are a wealth of resources for understanding the basics and newest advances in ultrasound.

August 15, 2018

Inspection Technology Review for Automotive Bead Dispensing Process

The industry is trending toward 3D for inline bead inspection.

August 8, 2018

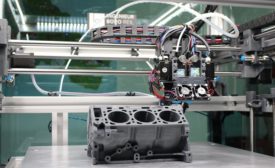

Additive Manufacturing Standards Aim to Keep Pace with Technology

ASTM launches Additive Manufacturing Center of Excellence with industry partners.

August 1, 2018

Solving Dimensional Problems

Measuring devices are usually worth a first look.

August 1, 2018

Tensile Testing Principles: Fundamentals, Methods and Challenges

Tensile testing can determine the component’s suitability for use and its performance over time.

August 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing