Test & Inspection

Digital Advancements for Shop Floor Inspection of Medical Devices

A wide range of inspections and verifications are needed for these parts.

August 1, 2017

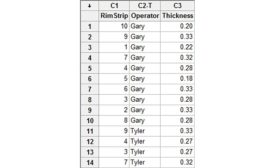

Is Your Measurement System Adequate?

If you can’t trust your measurement system, then you can’t trust the data it produces.

August 1, 2017

INDUSTRY HEADLINE

Jesse Garant Metrology Center Invests $15 million to Expand Part Inspection Services

July 20, 2017

INDUSTRY HEADLINE

Former Boeing CTO John J. Tracy Brings Aerospace Expertise to 3D Systems Board of Directors

July 11, 2017

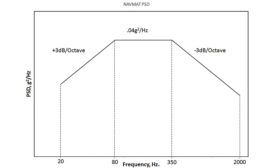

Repetitive Shock or Electro-Dynamic: Which Vibration System Will Meet Your Needs?

ED and RS systems generate vibration through very different mechanisms, resulting in different fatigue characteristics.

July 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing