Management

INDUSTRY HEADLINE

Hans Vestberg Will Resign as Vice Chairman of Hexagon's Board

July 9, 2018

Coordinate Metrology Society

Metrology: An Occupation for Future Growth

Skills gaps and shortages create demand for workers and education.

July 8, 2018

Analyzing Potential Failure

Failure modes and effects analysis is an effective method.

July 8, 2018

3D Printing, Big Data, 100 Percent Validation, and Other Aerospace Manufacturing Trends

Aerospace is leading the way in the IIoT, with a heightened focus on additive manufacturing, the digital thread, and lightning-fast 3D measurement and inspection technologies.

July 8, 2018

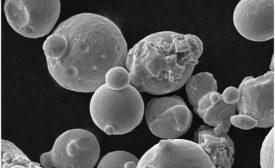

Producing Quality Metal Parts with Additive Manufacturing

Learn more about the entire 3D printing process from powder characterization to determining the best tests to qualify parts for the aerospace industry.

July 1, 2018

AS9100 Certification: Why and What Next

The standard says that people should understand the importance of what they do.

July 1, 2018

The Effects of Automation

Modernization creates more jobs than it eliminates.

July 1, 2018

INDUSTRY HEADLINE

Global Shop Solutions Celebrates 25-Year Anniversary of Erika Klein, Vice President of R&D

June 20, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing