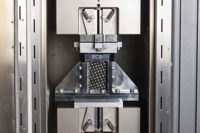

Wide acting grips keep specimen in place. Source: Instron

Mechanical characterization of the properties of polymers is critical in the development and manufacturing processes, as well as in the quality control and ultimately in determining the functionality of a finished product. Polymers find applications in virtually every facet of human activity and industry-from packaging to automotive, electronics to healthcare, and construction to aerospace. The list is endless.

Flow property determination and thermo-mechanical testing are vital during the formulation and optimization of any polymeric material. Understanding polymer properties such as viscosity, melt flow rate, softening point, ultimate tensile strength, modulus, Poisson’s ratio and impact resistance are critical as a polymer material moves through its lifecycle of raw material to compound to semifinished to finished product.

Most often, meeting internationally-recognized testing standards as defined by ISO or ASTM or other industry-related standards are the reasons why materials testing is performed.

The thermal conductivity of polymer melts is one of the most challenging material properties for polymer processing as it influences the temperature distribution during the process and the cooling behavior of the polymer melt. Heat dissipation data of polymers melts are seldom available, particularly at different pressures, but it is necessary to obtain this piece of information for high-end process simulations in order to minimize uncertainties and determine the aspects affecting the process, as well as the quality of finished parts.

Calculations have proven that measurements of different polymeric materials, in a wide range of testing conditions, are consistent with those experienced in polymer processing applications. Materials with optimized thermal conductivity properties have a more homogeneous temperature distribution during the process, a lower tendency to defect and a better cooling behavior.

Tensile testing of polymers to ISO 527-2 or ASTM D638, and calculating Poisson’s Ratio is one of the more challenging calculations to obtain repeatable and accurate results. Reproducibility studies have shown great variance in the measurement of Poisson’s Ratio, revealing inconsistent results between labs. Difficulty in measuring the ratio relates directly to the measurement of transverse and axial strain at very small strain ranges. Poisson’s Ratio is typically measured at strain values between 0.05% to 0.25%.

In addition to an extensometer with the appropriate accuracy, setting up an appropriate test method is critical for achieving accurate, repeatable results. A preload improves the repeatability of results by eliminating compressive forces on specimens that often result when the specimen is initially placed into the grips. Compressive forces may cause specimens to bow, resulting in inaccurate results. The preload value should be high enough in order to straighten a specimen without stretching it. Some materials testing software packages include automatic preload as a standard feature; however, not all software packages have this feature. In these cases, operators must apply preloads manually.