Home » manufacturing

Articles Tagged with ''manufacturing''

Here are some things organizations can do right now to keep pace with changing technology -- and help polish the field's image.

Read More

The Unfolding Course of Events

Looking to the past provides some perspective.

June 30, 2020

Ask the Expert

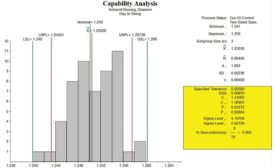

Capability Analysis

This first column will focus on this technique.

June 25, 2020

Save Time with Auto Ballooning

By auto ballooning various model types, companies can complete forms faster.

June 1, 2020

Three Manufacturing Trends that Meet the Need for Speed

The business world, including the manufacturing sector, seems to move a little faster every day.

June 1, 2020

Compliance Today

No matter what is going on in the world, you can feel prepared.

June 1, 2020

Producing Additively Manufactured Parts

The future of additive manufacturing will include an increasing number of production applications.

June 1, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing