Home » manufacturing

Articles Tagged with ''manufacturing''

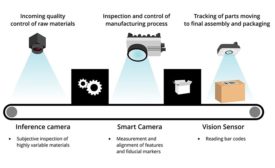

Smart Camera Evolution

The evolving capabilities of cameras with onboard intelligence are creating new opportunities for the industry.

May 1, 2019

Electronics & Quality

Evaluating the physical properties of electronic devices and parts.

May 1, 2019

Drive Improvement with Data

Achieve greater insight into the operations and make decisions based on data.

May 1, 2019

How a Global Manufacturer Prevents Defective Parts with SPC Software

Easy monitoring and actionable reporting are key.

April 30, 2019

Sponsored Content

White Paper: CMM or Portable Metrology

How to Choose the Most Effective Measuring Tool

April 24, 2019

Sponsored Content

Understanding Quality Planning best practices to establish and meet quality standards and drive productivity

April 19, 2019

Sponsored Content

Repeatability, Reproducibility and Traceability for Medical Compliance

April 10, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing