Home » CMM

Articles Tagged with ''CMM''

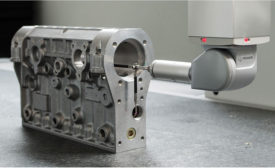

Metrology Looks Towards Automation

Metrology and inspection solutions aim to stay in-line with factory automation.

December 1, 2016

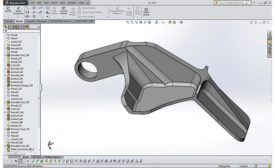

Understanding the power and complexity behind a CMM allows the operator to maximize productivity.

Unleash Your CMM’s Potential

December 1, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing