Home » radiography

Articles Tagged with ''radiography''

Modern technology is closing the technology and accessibility gap between N-ray and X-ray imaging.

Read More

NDT Trends

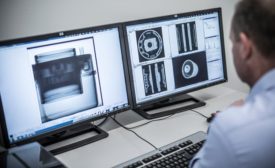

Remote Evaluation of Radiographic Images

Let’s examine the application of remote radiographic evaluation and the subsequent commercial benefits for business.

August 5, 2020

Radiographic Image Interpretation: Doing it Right

The process of radiographic interpretation consists of many variables with the major objective being achieving the highest possible quality level.

June 11, 2020

Easing the Inspection Task

Recent developments in various NDE modalities are making inspection more accurate and faster while providing data that is easier to interpret.

June 10, 2020

Using Phased Array UT for Austenitic Weld Inspections

How the latest phased array ultrasonic testing tools and techniques allow more productive NDT.

June 1, 2018

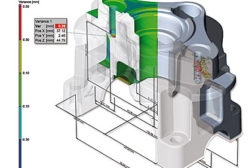

Radiography Trends Lead to High Speed CT

Today’s digital radiography is far beyond what early radiographers could have imagined.

April 2, 2018

Industrial X-ray CT: Quality Control from the Lab to the Production Floor

Recent speed and accuracy developments have allowed the migration of CT technology.

June 9, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing