Home » lenses

Articles Tagged with ''lenses''

Vision & Sensors | Sensor Trends

Lens and camera manufacturers need to collaborate to develop new mounting standards for the new, large sensor formats already on the market, as well as the ones that will be introduced.

Read More

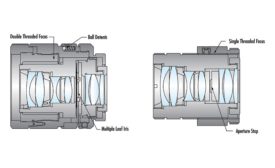

Ruggedization of Machine Vision Lenses

As applications and markets diversify their environmental profiles, the technology and optics must do the same.

November 29, 2020

Machine Vision Systems Design: The Basics

Systems integration is the process of bringing together diverse and disparate components and sub-systems and making them function as a single unified system.

September 1, 2020

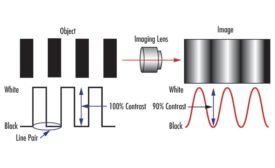

Deciphering Lens Specifications and Choosing the Proper Lens

In the past, cameras were once the limiting component for performance in and imaging system. Today, lenses have become the critical component in many applications.

March 2, 2020

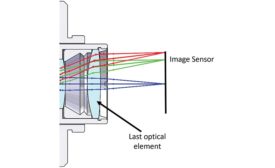

Design Considerations for New High Resolution and Frame Rate CMOS Sensors

Sensors will continue to evolve, and camera lenses will continue evolving right along with them.

January 1, 2020

Sponsored Content

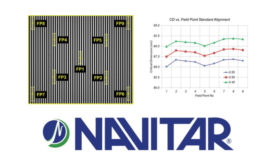

Improvements in Machine Vision Accuracy with Lens-Sensor Active Alignment

July 1, 2019

5 Considerations for Modern Smart Camera Design

The goal is to create smart cameras that can do it all. How do we get there?

April 30, 2018

Machine Vision Applications: The Process of Developing a Complete Solution

The first step is to establish the requirements and determine if it is possible.

September 1, 2017

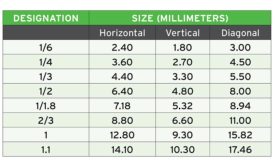

Choosing a Lens for Machine Vision

Not surprisingly, with the enormous range of sensor formats and resolutions available in machine vision cameras, there are many options for lenses.

September 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing