Home » additive manufacturing

Articles Tagged with ''additive manufacturing''

TEST & INSPECTION

As Manufacturers Embrace Increasingly Complex Materials and Processes, Their Inspection Methods Evolve with Them.

Read More

Additive Drives the Adoption of CT for Nondestructive Internal Inspection

CT provides unparalleled insight into a 3D structure, including its density at every point throughout its volume.

November 30, 2020

Reverse Engineering Software 101

It is the process of converting a physical part into a digital form.

May 1, 2020

Quality Headline

New ASTM International Group Will Help Expand Applications of Additive Manufacturing Technologies

January 21, 2019

INDUSTRY HEADLINE

Volkswagen Selects Additive Industries’ MetalFAB1 for Industrial 3D Metal Printing

November 13, 2018

INDUSTRY HEADLINE

UL Chemical Safety Research and Georgia Institute of Technology Release Pioneering 3D Printing Research

Studies identify a potential health risk from emissions released from 3D printers.

November 12, 2018

INDUSTRY HEADLINE

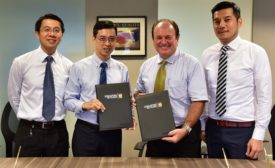

Renishaw and Singapore Polytechnic Collaborate to Promote Metal 3D Printing

October 22, 2018

INDUSTRY HEADLINE

ASTM International Additive Manufacturing Center of Excellence Announces First Round of R&D Projects

September 18, 2018

INDUSTRY HEADLINE

Fast Radius Opens Headquarters and Additive Manufacturing Factory in Chicago‘s West Loop

August 28, 2018

INDUSTRY HEADLINE

ASTM International to Host November Symposium on Additive Manufactured Parts

August 23, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing