Home » flaw detection

Articles Tagged with ''flaw detection''

NDT | NDT in Aerospace

As the number of flights is expected to keep increasing over the years, flaw detection is critical to safe air travels.

Read More

Test & Inspection

In-situ Monitoring for Additive Manufacturing: Opportunities and Challenges

As parts become more complex and are used in more critical applications, the need for in-situ monitoring grows.

September 18, 2023

NDT | Flaw Detection

Flaws Come in Different Shapes and Sizes

The origin of a flaw can come from many different sources, and they can be anywhere within a part.

August 10, 2023

NDT | Back 2 Basics

Flaw Detection 101

Each NDT method has its advantages and disadvantages, so knowing what your flaws of interest are and where they tend to be located can be extremely helpful.

June 9, 2022

NDT Flaw Detection

How Remote Visual Inspection Technology Contributes to a Safer World and a Robust Global Economy

Remote visual inspection products enable us to see and evaluate defects in machinery and industrial equipment.

November 8, 2021

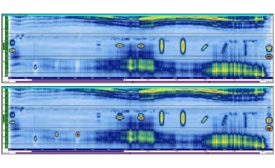

A New Angle on Aerospace FSW Inspections

The most effective inspection method for friction stir weld flaws is phased array ultrasound.

July 1, 2020

What Is a Digital Microscope?

A digital microscope can perform the same tasks as an optical microscope, but it comes with extra benefits.

March 10, 2020

NDT Flaw Detection 101

We’re always faced with deciding which nondestructive testing method is the most appropriate for detecting a specific flaw type.

April 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing