Home » flaw detection

Articles Tagged with ''flaw detection''

Perfecting Your Manufacturing Eddy Current Test

How to specify a proper eddy current test and develop a prototype to validate your test assumptions.

June 1, 2017

Optical Metrology Sees More

No other measuring method is capable of evaluating so many data points as quickly and as precisely as optical systems can.

May 1, 2017

Flaw Detection Tutorial: Quantifying and Qualifying Flaws

Setting up flaw detection is not without its challenges.

November 5, 2015

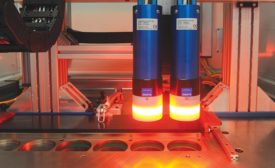

Nondestructive Flaw Detection in Metallic Components

A closer look at liquid penetrant and magnetic particle inspection, ultrasonic testing and eddy current testing.

August 4, 2015

NDT in Aerospace

Ultrasonic Bond Testing as a Quality Tool

With the growth in the use of adhesive bonding and composites, bond testing is seeing its second wind.

July 9, 2014

Improved Flaw Detection

Technological advancements in distance gain sizing result in greater inspection accuracy and reliability.

February 3, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing