Home » CNC

Articles Tagged with ''CNC''

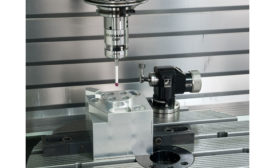

Boost Productivity, Profits with Active Controls

Increasing machine uptime has never been easier.

April 10, 2018

Staying Error-Proof with Ballbar Testing

Smart, wireless ballbars keep a wide range of businesses competitive.

March 13, 2018

Predictive Controls Level the Playing Field for the Next Manufacturing Workforce

Students at the Center for Manufacturing Innovation use automated setting for fast, accurate and repeatable metal cutting operations.

February 6, 2018

INDUSTRY HEADLINE

TriMet Consulting to Serve CNC and CMM Programming Needs of Manufacturers

April 17, 2017

INDUSTRY HEADLINE

Siemens Partners with U.S. Technical Schools for L.E.A.P. initiative

February 16, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing