Home » hardness testing

Articles Tagged with ''hardness testing''

Hardness testing functionality has evolved.

Read More

Predictive Measures: How Rockwell Hardness Testing Supports Modern Material Evaluations

Rockwell testing is the most commonly conducted hardness testing, as the testing procedure is simple and the readings can be directly attained from the testing machine.

November 8, 2018

New Developments for Magnetic Hardness Testing

Learn more about hardness measurement without an indenter via the magnetic measurement method.

November 1, 2018

Cutting Edge Hardness Testing

Accurate testing for hardness is vital to ensure a high quality product.

February 1, 2017

Test & Inspection

How to Deal with the Difficulties of Microhardness Testing

We’ll cover some of the common problems associated with microhardness testing and address some of the techniques and technologies that can be used to avoid them.

May 1, 2016

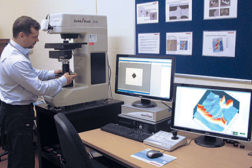

Automation Drives Vickers Hardness Testing Into the 21st Century

The Vickers test is well suited to characterization of materials with extremely hard surfaces.

February 2, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing