Home » 3D Inspection

Articles Tagged with ''3D Inspection''

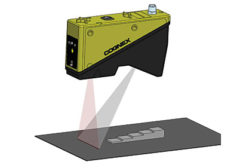

3-D Vision Improves Performance of Challenging Inspection Applications

IN CONTRAST TO TRADITIONAL MACHINE VISION SYSTEMS THAT PROVIDE INFORMATION IN TWO DIMENSIONS, 3-D PROVIDES MORE INFORMATION ABOUT MANUFACTURING PROCESSES.

December 10, 2014

Vision & Sensors - Case Study

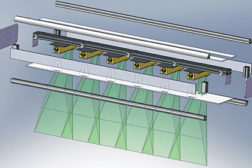

Integrating A 3-D Inspection System

A major manufacturer of building materials wanted to add 100% inline dimensional inspection to its manufacturing line.

May 13, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing