Home » reverse engineering

Articles Tagged with ''reverse engineering''

Reverse engineering parts and systems enable aircraft to keep flying or machines to keep running.

Read More

Who’s the Keeper of GD&T Data?

GD&T is widely considered to be an essential tool for communicating design intent and ensuring parts meet the desired form, fit, function and assembly.

August 1, 2016

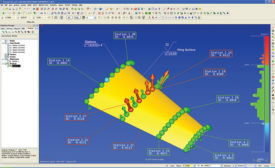

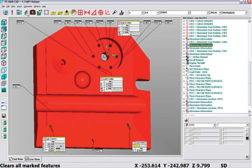

Reverse Engineering: A Practical Perspective

With the right tool set the process of reverse engineering is pretty straightforward.

February 2, 2015

Software & Analysis

Choose the Right Tools for Reverse Engineering

The term “reverse engineering” means different things to different people.

May 2, 2014

Software & Analysis

Modern Reverse Engineering of 3-D Geometry

The purposes for reverse engineering are many and varied, ranging from the need to reproduce an existing product lacking CAD documentation to acquiring sensitive information to determine possible patent infringement

May 1, 2014

Software & Analysis

Reverse Engineering: Backing into Quality

The ability to reverse engineer is quickly becoming a standard go-to practice in manufacturing.

October 4, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing