Home » vision technology

Articles Tagged with ''vision technology''

The Versatility of Vision Metrology

In the manufacturing world, speed and accuracy are high priorities. Vision technology provides both.

September 1, 2016

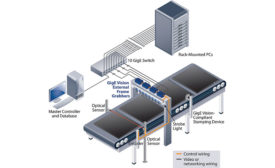

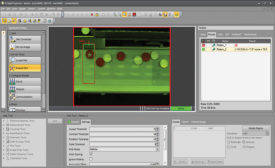

Vision Systems Continue to Provide Value

CURRENT VISION SYSTEMS HAVE COME A LONG WAY FROM PREDECESSORS.

July 8, 2015

Independent Quality Assessment: A Call to Arms for Quality Management

WHY WOULD THOSE RESPONSIBLE FOR THE DESIGN, FABRICATION AND ASSEMBLY PROCESS ALSO BE RESPONSIBLE FOR THE ASSOCIATED PRODUCT QUALITY INSPECTION?

March 3, 2015

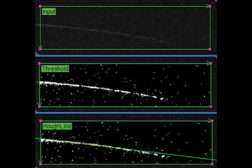

The Hough Transform in Machine Vision

Use good lighting and image preprocessing to get a strong signal before applying the Hough Transform.

November 3, 2014

Vision Measuring Systems Advance Noncontact Dimensional Measuring Technology

Today’s vision measurement systems and microscopes use various technologies for noncontact measurement. This article discusses five principal technologies that may be used to “find the edge.”

September 5, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing