Home » optical metrology

Articles Tagged with ''optical metrology''

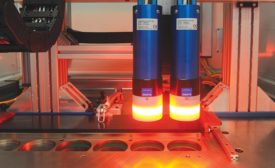

NDT | Automation

The aerospace industry is one example of where the marrying of automation and metrology is being adopted to elevate product quality and operational excellence.

Read More

Edge Break Analysis for 3D Optical Metrology

Handheld 3D metrology that uses edge break analysis software can bring precise edge break measurements to the shop floor.

August 3, 2020

Sponsored Content

How to Reach Unrivaled Precision in Distance and Thickness Measurements with Confocal Sensors

April 8, 2019

Getting Inspection Right the First Time

How to decide whether to contract measurement services when 100% inspection is required.

March 29, 2018

Optical Metrology Sees More

No other measuring method is capable of evaluating so many data points as quickly and as precisely as optical systems can.

May 1, 2017

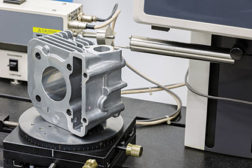

Opportunities and Challenges of Optical Metrology in Manufacturing

The latest technological advances open new opportunities with the right approach and the right equipment.

January 1, 2015

INDUSTRY HEADLINE

Olympus Hosts Tech Day at Smithsonian’s National Museum of Natural History

December 8, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing