Home » tensile testing

Articles Tagged with ''tensile testing''

6 best practices for ensuring productive, repeatable compression testing.

Read More

5 Common Errors in Tensile Testing

As with any testing, the data is only as good as the test methodology allows.

October 31, 2017

6 Popular Fatigue Test Applications

It’s used in applications ranging from dental implants to running shoes.

August 1, 2017

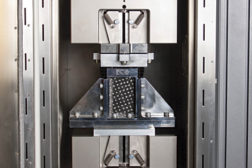

The Universality of a Universal Testing Machine

A staple of quality control laboratories around the world, a UTM is an indispensable asset to quality and engineering professionals.

April 1, 2017

Tensile Testing Machine Basics

Learn more about testing solutions available today.

October 1, 2015

Quality 101

Mechanical Testing of Composites

The mechanical testing of composite materials involves a range of test types, a plethora of standards, and the need to condition and test in a variety of different environments.

July 1, 2014

Measuring the Ductility of Metals

Ductility is defined as the ability of a material to deform plastically before fracturing.

June 1, 2007

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing