Home » lighting

Articles Tagged with ''lighting''

Vision & Sensors | Lighting

Computational imaging can simplify certain problems that are difficult to solve with standard visual imaging.

Read More

Vision & Sensors | Machine Vision 101

Machine Vision Lighting and Why It’s Important

When considering illumination, the object or field to be imaged is really what matters.

December 21, 2022

Vision & Sensors | Lighting

Three Challenges In Machine Vision Lighting Today And How To Solve Them

With increased speeds, dynamic production lines, and advanced inspection processes, smart automated lightng is driving machine vision solutions.

May 1, 2022

Test & Inspection

Shining A Light On Color Quality Control

Monitoring color during the entire production process can help manufacturers identify color drifts before they become a problem.

March 8, 2022

Vision & Sensors | Lighting

Simplify Deep Learning Systems with Optimized Machine Vision Lighting

Smart Lighting Improves Image Input Data for Effective Convolutional Neural Networks

July 8, 2021

VISION & SENSORS - MACHINE VISION 101

Engineered Lighting: Part 2 of 3

Learn how to choose a light source to take advantage of the characteristics that create contrast.

March 9, 2021

Lighting Basics for Machine Vision

With these steps you are well on your way to finding the right light to highlight the features needed for a great image.

November 30, 2020

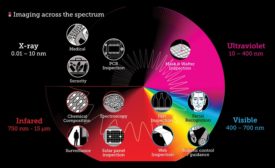

Cameras that See Beyond Visible Light: Inspecting the Seen and Unseen

Read on for a high-level overview of imaging technologies from across the electromagnetic spectrum.

September 1, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing