Home » cameras

Articles Tagged with ''cameras''

Seen, Stored, Learned

Read More

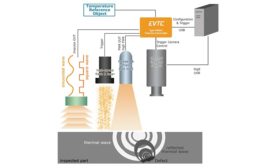

Thermal Imaging for Quality Control

A thermal imaging camera can make infrared light visible.

December 2, 2019

How Machine Vision Cables Impact Machine Vision Performance

Choosing high quality cables is your best approach for long-term productivity and consistent imaging data.

July 1, 2019

Articulating Video Borescope Diameters are Shrinking while Image Quality Improves

The name of the game is always higher resolution, greater detail, improved accuracy, and faster speeds.

June 3, 2019

Connected in Quality

Portable optical inspection system for composite materials with USB 3.0 camera provides reproducible measurement results including documentation.

May 15, 2019

Test & Inspection

Additive Manufacturing in Production Presents Challenges, Opportunities for Quality

Applying quality control measures to additive technologies requires a holistic approach.

May 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing