Home » metrology systems

Articles Tagged with ''metrology systems''

Measurement

Even the best machined parts can benefit from 100% sorting.

Read More

CMS Column | Justin Novak

Metrology and the EV Revolution

In a sector that’s going places, measurement is driving.

July 31, 2024

Lean Manufacturing

Why Lean Principles Stand The Test of Time

Although contexts and technologies change, waste categories are timeless.

October 3, 2022

Color Measurement

Is Your Color Workflow Resilient for Today’s Supply Challenges?

Capturing and analyzing color data can help identify areas for improvement.

October 1, 2022

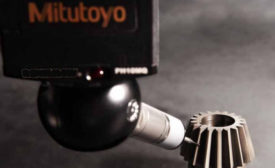

Measurement

Best Suited Options for Your Metrology Toolbox

When are non-contact structured light 3D scanners better suited than touch CMMs?

September 8, 2022

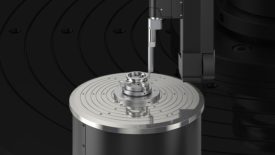

Measurement

Roundness Measurement Technology Drives Quality and Productivity

For certain parts and products, roundness measurement is a critical part of the quality assurance process.

August 1, 2022

Test & Inspection: Measuring Magnetic Properties

Measuring magnetic properties can determine the effect of heat treatment on a material

July 8, 2022

Test & Inspection: Hardness Testing of Coatings

There are a wide variety of testing techniques for hardness, using different principles and reporting different scales.

July 8, 2022

Today’s CMMs Are Known for Adaptability, Ease of Use

As the skills gap continues to impact the manufacturing field, skilled CMM users and programmers are harder to come by. In response, CMM companies have built the tools to be easier to operate and program.

July 8, 2022

Why In-Line Inspection Can Save Time and Money

To simplify and hasten the measurement process, manufacturers are bringing measurement to the production line for verification, minimizing the time needed to refine machining.

February 14, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing