Home » 3D vision

Articles Tagged with ''3D vision''

Recent Advancements in Vision Technology for Product Inspection

TODAY IT’S POSSIBLE TO OBTAIN THE BENEFITS OF MACHINE VISION ON A WIDER RANGE OF APPLICATIONS WHILE AT THE SAME TIME INCREASING INSPECTION ACCURACY AND REDUCING APPLICATION DEVELOPMENT TIME.

July 8, 2015

Automation

AUTOMATED MACHINE VISION SYSTEMS ARE FASTER, SMARTER AND MORE DETAILED THAN EVER.

March 3, 2015

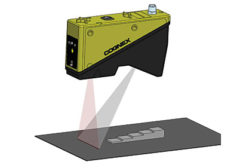

3-D Vision Improves Performance of Challenging Inspection Applications

IN CONTRAST TO TRADITIONAL MACHINE VISION SYSTEMS THAT PROVIDE INFORMATION IN TWO DIMENSIONS, 3-D PROVIDES MORE INFORMATION ABOUT MANUFACTURING PROCESSES.

December 10, 2014

Vision & Sensors - Imaging

3-D Imaging Enters the Machine Vision World

Consider these 3-D imaging techniques for machine vision.

March 5, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing