Home » First Article Inspection

Articles Tagged with ''First Article Inspection''

By auto ballooning various model types, companies can complete forms faster.

Read More

Error-Proof Your Inspection Reporting

How to quickly solve your missed requirements, out of tolerance and out of FAI compliance issues.

May 1, 2020

Evolving Quality Processes Propel Growth

All inspectors are initially trained in first article inspection and then on assembly, sheet metal, and CMM inspection.

April 8, 2020

Better Inspection Reporting

Automatically create inspection reporting for any industry.

April 2, 2020

At the Corner of Digital Twin and Perfect Part

Consider driving production with the shortest possible cycle time.

February 1, 2020

How to Create an AS9102 First Article Inspection Report

Despite the name, the inspected article may not necessarily be the “first” produced, but a sample from the first production run provided to the customer.

Read More

Vision System Assures Glass Act at California Shop

With the vision system in place, PG&O has substantially ramped up its inspection productivity.

April 30, 2018

Redefining Aerospace Inspection with CT

While many NDT methods are available, industrial computed tomography is redefining the limits of inspection.

October 17, 2017

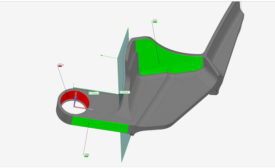

First Article Inspection with 3D Scanning

A growing number of companies are including this technology in their first article inspection procedures.

April 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing