Home » x-ray fluorescence

Articles Tagged with ''x-ray fluorescence''

Beginner tips to understand the role XRF plays in restricting hazardous materials.

Read More

With XRF Measurement, the Goal is Achieving Low Limits of Detection Precisely—and Fast

Here’s how to get there.

June 8, 2018

XRF 101: Choosing the Right Analyzer

Consider these seven points to help you identify what tool best meets your needs.

November 13, 2017

Triboluminescence: Enabling Major Advances in XRF

Triboluminescent X-ray generation has had a profound impact on XRF technologies.

October 17, 2017

INDUSTRY HEADLINE

MicroConnex Deploys High-Resolution Fischerscope X-Ray Fluorescence Metrology Station

August 4, 2017

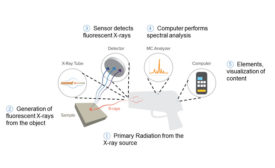

Choosing an X-Ray Fluorescence (XRF) Instrument

Energy Dispersive XRF systems are offered in a number of benchtop configurations and also in portable, handheld configurations.

April 9, 2015

Quality 101: XRF 101

Avoid costly process failures by utilizing XRF analysis

December 6, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing