Measurement

Measurement

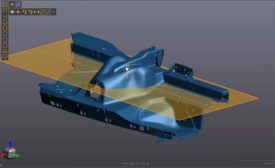

5-Axis CMM Measurement

CMMs of the Future will Provide Immediate Feedback to Help You be Proactive When it Comes to Planning Maintenance and Workload.

June 15, 2021

Other Dimensions | Hill Cox

Plain Ring Gage Calibration

Short Range Comparison Techniques are the Most Popular for Calibrating Plain Rings.

June 15, 2021

Why Yesterday’s Data Collection Systems Don’t Support Overall Equipment Effectiveness

Increasing the pace, capacity, and precision of measurement and inspection data collection is the first step in OEE.

June 11, 2021

How Process Control Saves Time and Money

Adding automation to manufacturing process control systems enables a holistic factory view.

June 10, 2021

Measurement

CMMs Go Collaborative

Is Your Coordinate Measuring Machine Future-Ready?

June 8, 2021

Quality 101

How to Choose the Best Shaft Measurement Tool for your Specific Application

There are Three Primary Options Available Today for Shaft Measurement: Optical, Tactile, and a Combination System

June 7, 2021

Quality Headline

Faro Expands Digital Twin Product Suite, Acquires HoloBuilder Inc.

June 7, 2021

Quality Headline

Dr. Ed Morse is New Director of UNC Charlotte’s Center for Precision Metrology

June 7, 2021

Speaking of Quality | Charles W. (Wes) Shelton

Measurement System Analysis More Than a Line on a PPAP Submission

June 1, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing