Measurement

Quality in Automation > Inspection

How to Automate your Inspection Process

New sensors, mobile systems and thorough communication can help manufacturers overcome previous hurdles.

April 4, 2020

Color Management 101: The Latest Technology and Techniques

Whether you are first introducing color control to your quality process or you are managing an existing framework, here’s what to know.

April 1, 2020

Additive Quality

The greatest challenge of AM is the verification of parts’ absolute reliability.

April 1, 2020

Quality Headline

Hexagon Enhances Simulation Solutions for Smart Factories, Smart Industrial Facilities With CAEfatigue Acquisition

March 17, 2020

Quality Web Exclusive

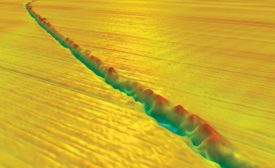

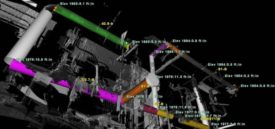

Exact Metrology Performs 3D Scan at Nuclear Power Plant

March 17, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing