Measurement

Measurement

Measurement Accuracy in Coordinate Metrology

Learn more about influencing factors, determination and optimization

April 1, 2014

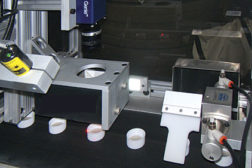

Measurement

Trends in Multi-sensor Measurement

Tactile and optical measurement techniques each have their advantages. Multisensor systems combine the strengths of both.

April 1, 2014

Other Dimensions

Calibration Cycles

Calibration frequency will vary with the application

April 1, 2014

Measurement

Measuring Thickness

It can be a bit more complicated than you’d expect.

March 3, 2014

Other Dimensions

Sending Ring Gages Out for Calibration

Ring Gages often require a little more attention

March 3, 2014

Customer-centered Focus Results in Integrated Innovations

CMM manufactures study customers to enhance user experience.

February 3, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing