Measurement

While manufacturers have applied model-based definition to product definition for some time, they have only recently applied it as a quality assurance process.

Read More

Understand Calibration Source Criteria (Pt 3)

There's more to calibration than reading digital displays.

March 2, 2015

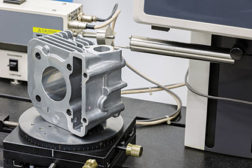

Mitutoyo Delivers Greater Productivity and Accuracy

Automotive supplier Dynamic Manufacturing benefits from CNC CMM.

March 2, 2015

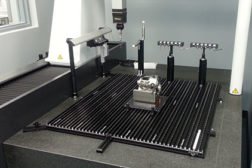

MFG Automation Integrator of Choicefor Large Scale Robotic Metrology

Challenge of precise, reliable inspection of 75-ton turbine solved by gantry-mounted robot.

March 2, 2015

INDUSTRY HEADLINE

AFM BioMed Conference Highlights Increasing Impact of Atom Force Microscopes in Biological Applications

February 26, 2015

Going Beyond Height With Height Gages

Here are some of the lesser known features built into today’s height gages that may help you not only make the measurement required but also speed it up and simplify it.

February 2, 2015

Calibration Source Criteria, Continued

CONSIDER THESE FACTORS IN YOUR CALIBRATION DECISIONS.

February 2, 2015

INDUSTRY HEADLINE

Hexagon Metrology and TriMet Announce Strategic Partnership

January 6, 2015

Opportunities and Challenges of Optical Metrology in Manufacturing

The latest technological advances open new opportunities with the right approach and the right equipment.

January 1, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing