Test & Inspection

Growing acceptance changes manufacturing processes.

Read More

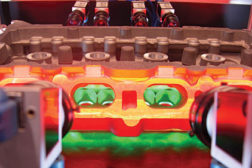

Turnkey Machine Vision Systems

Today’s tools can make even the most difficult vision inspections plausible

December 10, 2013

Change Detection for Machine Vision Applications

Finding the differences between images can lead to improved product quality

December 10, 2013

Case Study: Mitutoyo Helps Ramcel Clear Hurdle of Complex Fixturing

Vision system facilitates measurement when heavy fixturing constrains access to a workpiece

December 6, 2013

Quality 101: XRF 101

Avoid costly process failures by utilizing XRF analysis

December 6, 2013

Test & Inspection

Digital Radiography for Aviation and Aerospace

The conversion from X-ray film technology to digital inspection systems eliminates cost-intensive film procurement and storage.

November 22, 2013

NDT - Equipment

Computed Radiography Offers a Range of Benefits

As more inspectors have turned to CR, the inspection equipment has been steadily improving, offering manufacturers faster and more precise and cost-effective NDT results than ever before.

November 20, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing