Test & Inspection

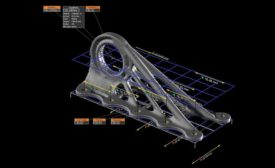

Keeping Up with Additive Manufacturing

AM production enables the creation of parts not possible with traditional technologies through new design concepts, new materials, and new applications, but still presents challenges.

December 1, 2020

Additive Drives the Adoption of CT for Nondestructive Internal Inspection

CT provides unparalleled insight into a 3D structure, including its density at every point throughout its volume.

November 30, 2020

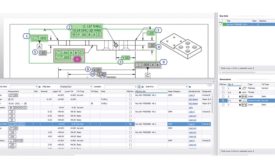

Three Cornerstones of Smart 3D Machine Vision

Modern UI design, web-enabled 3D smart sensors, and onboard inspection software.

November 28, 2020

How Artificial Intelligence overcomes major obstacles standing in the way of automating complex visual inspection tasks

From accommodating flexibility to minimizing overdetection, the latest AI algorithms have the necessary capabilities to match the sensibility and expertise of professional human inspectors.

November 27, 2020

Spectroscopy Explained

Spectroscopy is the branch of science dedicated to the investigation of electromagnetic spectra produced from the interaction between a sample and an energy source.

October 29, 2020

Quality Headline

ATEQ Corp, Vacuum Instruments Corporation Form Strategic Partnership

October 27, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing