Test & Inspection

NDT - Phased Array

Automation and parallel phased array systems are being used to meet challenging inspection and production requirements.

Read More

NDT - Training

The Nondestructive Testing (NDT) Training Industry

Primed for expansion

October 9, 2013

Measurement

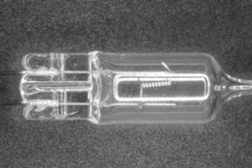

How to Choose the Right Lighting for Machine Vision Applications

“The most sophisticated automated inspection system in the world cannot work without the proper lighting.”

October 3, 2013

Test & Inspection

A Turn for the Better: Advances in Multisensor Systems

Multisensor systems allow complex parts to be easily measured in one setup using the best sensor for each measurement situation.

October 1, 2013

DMSC Submits QIF v1.0 for ANSI Standardization

A new interoperability standard for Manufacturing Quality Measurement Information

August 23, 2013

NDT - Back 2 Basics

Wire Crimp Pull Testing

Achieve consistent product performance with wire crimp pull testing

August 14, 2013

NDT - Hardness Testing

Portable Hardness Testing Methods

Consider these devices for use in the field.

August 8, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing