Software

Quality Web Exclusive

How to Create a Culture of Quality Across the Supply Chain

May 9, 2019

Software & Analysis

There’s Nothing Artificial About AI in Quality

Articial intelligence is making its way into the workplace.

May 8, 2019

Quality Headline

Hexagon’s Manufacturing Intelligence Division Breaks Ground on New Center of Excellence

May 7, 2019

Quality Headline

Hexagon Hosts the MSC Software Global User’s Conference at HxGN LIVE

May 3, 2019

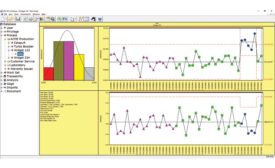

Drive Improvement with Data

Achieve greater insight into the operations and make decisions based on data.

May 1, 2019

How a Global Manufacturer Prevents Defective Parts with SPC Software

Easy monitoring and actionable reporting are key.

April 30, 2019

Quality Headline

Hexagon Hosts Second Annual Production Software Users' Group Meeting at HxGN LIVE 2019

April 8, 2019

Move from “Inspect and Reject” to “Predict and Prevent” with SPC Software

A senior quality leader details his approach to making significant quality improvements.

April 2, 2019

How to Statistically Control the Process

When disruptions are detected, it’s critical that operators have the tools available to quickly diagnose and correct the issues.

April 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing