Management

Why Adopt Risk-Based Thinking?

Automated risk management tools can help manufacturers incorporate risk-based thinking into their processes.

June 3, 2021

Speaking of Quality | Charles W. (Wes) Shelton

Measurement System Analysis More Than a Line on a PPAP Submission

June 1, 2021

Quality Headline

Hexagon, Plex Systems Announce Partnership to Deliver Smart Manufacturing Solutions

June 1, 2021

Quality Headline

Gaps Progress Report Available: America Makes, ANSI Standardization Roadmap for Additive Manufacturing

May 11, 2021

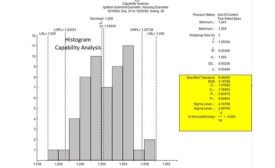

Ask the Expert | Dr. Sophronia Ward

Capability Analysis Follow-Up

Here we'll cover the specifics of a capability analysis and several sticking points in interpreting and taking action on information from the analysis.

May 7, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing