Vision & Sensors

VISION & SENSORS - AUTOMATION

Automation will give, as well as take, opportunities for human workers.

Read More

VISION & SENSORS - AUTOMATION

How Augmented Reality Can Support Industry 4.0

With the introduction of augmented reality into assembly and inspection processes, cutting-edge industry 4.0 research is uncovering best practices to maximize quality.

March 9, 2021

VISION & SENSORS - MACHINE VISION 101

Engineered Lighting: Part 2 of 3

Learn how to choose a light source to take advantage of the characteristics that create contrast.

March 9, 2021

VISION & SENSORS - LENSES

Protecting Lenses

Imaging systems have specific design requirements to maintain performance without degrading over time.

March 9, 2021

VISION & SENSORS - SENSOR TRENDS

Event-Based Vision: Taking a Cue From Biology

We can replicate the efficiency of how our eyes work with a new form of vision capture called event-based vision.

March 9, 2021

Vision & Sensors Headline

Elementary Robotics Appoints New EVP of Sales and Marketing, EVP of Engineering

March 2, 2021

Vision & Sensors Headline

Vision Engineering Inc. Celebrates 40 Years by Helping to Feed America

February 8, 2021

Vision & Sensors Headline

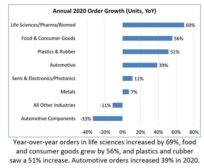

For First Time on Record, Yearly Non-Automotive Robotic Orders Higher Than Automotive Orders

January 31, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing