Automotive

Back to Basics: Impact Testing

Beginner tips to understand impact test methods and standards.

September 4, 2018

INDUSTRY HEADLINE

Burke Porter Group Acquires Auburn Hills-Based WinterPark Engineering

September 4, 2018

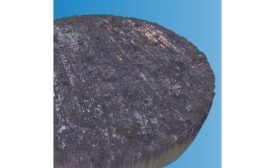

Fully Characterizing Brake Pad Materials to Improve Performance and Lower Development Costs

Combining benchtop mechanical testing of smaller brake material samples with rapid 3D surface metrology makes it possible to analyze results more quickly than ever before.

September 1, 2018

INDUSTRY HEADLINE

U.S. and Canadian Manufacturers: We Must Have a Trilateral Agreement

August 31, 2018

INDUSTRY HEADLINE

Safety, Labor And Connectivity Drive Innovation At IMTS 2018 Machine Components/Cleaning/Environmental Pavilion

August 29, 2018

INDUSTRY HEADLINE

Machine Control Providers at IMTS 2018 to Focus on Connected Systems

August 16, 2018

INDUSTRY HEADLINE

Dates Confirmed for Ideagen’s European Customer Conference, ‘Ideagen Horizons’

August 10, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing