Featured on Home Page

Management

Dr. Rochelle Cook of California State University Dominguez Hills describes her route to quality.

Read More

Automation

How Automation Can Help You Achieve Your Growth Targets

The work that employees enjoy least is generally the most suitable for automation.

April 22, 2024

Automated Inspection

Automating EV Battery Tray Inspection Increases Speed of Information

Many EV manufacturers are still searching for the optimal inspection method for the battery tray.

April 19, 2024

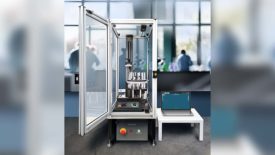

Test & Inspection

Universal applications and implementations of UTMs

A universal tester can regularly be found implementing tension and compression applications in QC and R&D environments.

April 18, 2024

Quality 4.0 | Dr. Milton Krivokuca

Developing a Quality 4.0 Quality Management System

The value of a QMS is its ability to be flexible in supporting continuous improvement and assuring customers are satisfied.

April 17, 2024

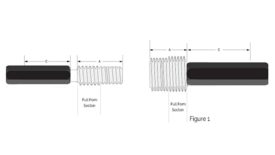

Gaging

Setting Thread Rings for Accurate Quality Checks: A Step-by-Step Guide

Following these steps meticulously will guarantee the ongoing reliability and effectiveness of your thread ring gages.

April 16, 2024

Software

How FMEA is Adapting Over Time, Part 2

There’s a growing understanding that not all manufacturing or production jobs are the same, and thus, the application of FMEA should vary accordingly.

April 15, 2024

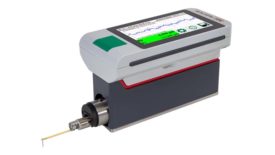

Measurement

Ensuring Precision: A Guide to Calibration in Surface Finish Measurement

The calibration process for surface finish units is simple but essential to the manufacturing process.

April 12, 2024

Quality 101

Understanding the Fundamentals of a Manufacturing ERP System

The common purpose of all ERP systems is to enable operational excellence, profitability and growth.

April 11, 2024

Meet the 2024 Quality Rookie of the Year: Justin Wise

Always Looking for the Next Challenge and Continuous Improvement

April 10, 2024

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing