Featured on Home Page

NDT | Ethics

A whistleblower shares his story.

Read More

ASNT Column | Muriel Magloire

Enhancing Safety Through Nondestructive Testing (NDT): Preventing Catastrophes and Ensuring Integrity

NDT plays a major role in preventing disasters and upholding safety standards.

March 12, 2024

Quality Headline

ISO now REQUIRES management to consider “climate change’ in your MSS

March 8, 2024

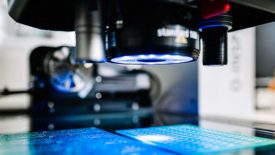

Measurement

Metrology and Microscopy for Electronics Quality Assurance — in One Machine?

Compliance can often only be achieved through both metrology and microscopy tools.

March 5, 2024

Measurement

Why Dimensional Air Gages Work So Well

The air gage is unmatched in its ability to gage parts with hard to reach features that in some cases would be impossible with any other method.

March 4, 2024

NDT | Ultrasonics

Smart Inspection: Latest developments and novel approaches in industrial ultrasonic testing

Compact design and automation are important aspects in meeting the inspection requirements of today and the future.

March 1, 2024

2024 Quality Plant of the Year: 3D Engineering Solutions

This Cincinnati-based company is a world class operation.

March 1, 2024

The Quality Show South

Podcast: An Aerospace Whistleblower Shares His Story

February 29, 2024

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing