Featured on Home Page

Test & Inspection

Your choice can be simplified by knowing what kind of information you need to collect.

Read More

Vision & Sensors | System Integration

Quality Inspection with AI Vision

What to know before you start using it.

March 8, 2023

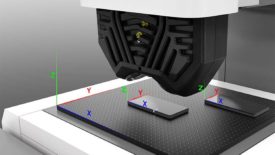

Vision & Sensors | Inspection

Exploring Integrated Optical Inspection Systems

For noncontact surface characterization of manufactured materials.

March 6, 2023

Measurement

Selecting The Right Solution For Shaft Inspection

Shaft measurement can be accomplished in many different ways, according to the needs of the manufacturing process.

March 3, 2023

Quality 101

Taper Pipe Thread Inspection, NPT

If you take care of your gages, they will take care of you and the parts you manufacture.

March 2, 2023

Quality Plant of the Year Winner

2023 Quality Plant of the Year: Reed Switch Developments

The annual Quality Plant of the Year has a strong past and a bright future.

March 1, 2023

From the Editor | Darryl Seland

Risk Versus Reward

What would you give up now for something potentially greater in the future?

February 20, 2023

Speaking of Quality | Tash Baksh

Common Pushbacks that Quality Professionals Hear

These situations are going to keep coming. Here's how to deal with them.

February 20, 2023

NDT | Magnetic Particle Inspection

Magnetic Particle Inspection Is Here to Stay

While magnetic particle inspection techniques have stood the test of time, the equipment involved has seen updates to keep up with demand, experts say.

February 16, 2023

NDT | Force Testing

Measuring Force Data in Extreme Conditions

Manufacturers want more data in the product development process to create better products, and they need solutions that can perform in any condition.

February 15, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing