Articles by Michelle Bangert

Increasing Productivity with CMM Automation

Discover how shop floor equipment can simplify your measurement process.

August 1, 2019

Quality & Corrective Actions

Ensure compliance with a robust corrective action process.

July 31, 2019

It’s All About the Customers

This quality management principle is perhaps the most important.

July 1, 2019

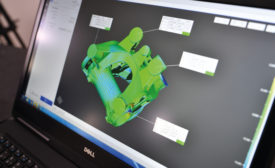

3D Scanning with Metrology

Metrology applications can benefit from the speed and data available from 3D scanning.

July 1, 2019

The Current State of Quality

Take a closer look at the ever-changing quality profession.

June 8, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing