Articles by Dr. Sophronia Ward

Software

The primary challenge for quality professionals is not acquiring sufficient data but collecting the right data and analyzing it correctly.

Read More

Ask the Expert | Dr. Sophronia Ward

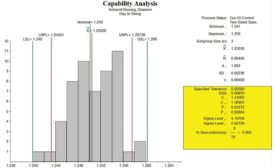

Capability Analysis Follow-Up

Here we'll cover the specifics of a capability analysis and several sticking points in interpreting and taking action on information from the analysis.

May 7, 2021

Ask the Expert

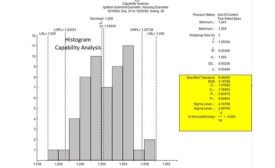

Capability Analysis

This first column will focus on this technique.

June 25, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing