ARTICLES

Software

The field of TQM software has become crowded as more vendors attempt to enter the space, experts say.

Read More

Software & Analysis

How ERP Software Impacts Quality

The right solution enables businesses to track and measure the total cost of quality.

March 1, 2022

Test & Inspection

How AI and Machine Vision Intersect

No matter how you slice it, machine vision has become more capable.

February 1, 2022

Vision & Sensors | Machine Vision Trends

The Rise of Machine Vision

Machine vision is increasingly used in applications outside the factory.

January 1, 2022

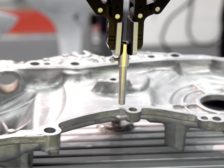

Measurement

The Future of CMMs

Although the CMM has been around for more than half a century, advancements have allowed it to maintain its position as the go-to technology for quality inspection.

November 1, 2021

Software & Analysis

Gaging Software’s Changing Role

As manufacturers become leaner and integrate metrology in innovative ways, openness and interoperability are paramount.

October 8, 2021

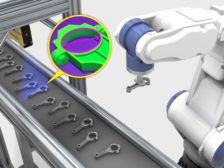

Vision & Sensors | Vision Robotics

How AI and Machine Vision Impact Vision Robotics

Just as humans need good data to make better decisions, so do AI systems.

September 1, 2021

Test & Inspection

How the Pandemic and Quality 4.0 are Changing Testing and Inspection

To discuss trends in testing and inspection, we must first discuss the impact of Covid-19.

August 8, 2021

Vision & Sensors | Machine Vision 101

Image Analysis 101: The Role of Artificial Intelligence

A Growing Number of Manufacturers are Using Deep Learning Tools, a Subset of Artificial Intelligence, to Reduce Waste and Improve production. But, Experts Say, Some of it is Just Hype.

July 6, 2021

TEST & INSPECTION

Changing Face of Additive Manufacturing Inspection

As Manufacturers Embrace Increasingly Complex Materials and Processes, Their Inspection Methods Evolve with Them.

June 1, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing