Articles by Edward McMenamin

Users from electronics manufactures to paleontologists see benefit of nondestructive inspections.

Read More

Using CMMs for Surface Finish Measurement

Advancements in motors and sensors improve CMM surface measurement capabilities.

June 15, 2018

Back to Basics: Material Testing Carbon Fiber Reinforced Plastics

An expert explains how to transition from testing polymers and metals to CFRPs.

June 1, 2018

Solving 3D Measurement Challenges Posed by Reflective Surfaces

Confocal white light provides an alternative to traditional laser scanning, allowing for non-contact measurement of shiny and translucent parts.

June 1, 2018

Back to Basics: Compressive Testing for Rigid Plastics

An expert discuses compressive test methods and ASTM D695.

May 1, 2018

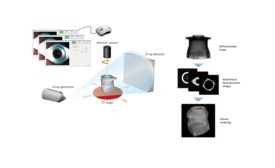

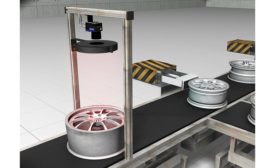

Computed Tomography Analysis Techniques

Industrial computed tomography cuts deep for applications beyond just porosity analysis.

April 2, 2018

Getting Inspection Right the First Time

How to decide whether to contract measurement services when 100% inspection is required.

March 29, 2018

Back to Basics: Flexural Testing for Plastics

A look at flexural test methods and ASTM D790

March 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing