Articles by Edward McMenamin

To fulfill potential, additively manufactured parts must stand up to fatigue testing.

Read More

CMMs Offer Multiple Applications for the Shop Floor

Once limited to the lab, CMMs are finding a home in harsh manufacturing environments.

February 1, 2018

Back to Basics: Six Sigma

A Six Sigma Master Black Belt provides an introduction to the methodology’s basic ideas and concepts.

January 1, 2018

The Next Generation of Manufacturing Professionals

Recruitment, diversity and outreach are key to filling the manufacturing jobs of the future.

December 7, 2017

A Fresh Look at Cost of Quality

Quality professionals must learn to speak the language of management.

November 6, 2017

QUALITY EXCLUSIVE

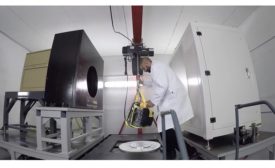

CT Scanning Steps Towards the Future

High-powered CT scanning allows for better inspection of 3D-printed parts.

October 23, 2017

The Lie of the Eyes

Spectrophotometers and colorimeters take the guesswork out of color measurement.

September 1, 2017

Connecting Through the Cloud

Data aggregation allows manufacturers to see previously invisible problems across the enterprise.

August 1, 2017

Close, But Not Quite Home

Rising wages in China and a weak peso again make Mexico an increasingly attractive destination for manufacturing.

June 1, 2017

Helium Leak Testing

New automotive safety and functionality requirements drive helium leak detection growth.

April 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing