Articles by Edward McMenamin

The Growing Skills Gap in Manufacturing

Industry leaders battle an outdated perception of manufacturing work.

September 1, 2015

Remote Visual Inspection: Video Borescopesto NDT Standards

Today's video borescopes can help quickly view parts and flaws.

August 10, 2015

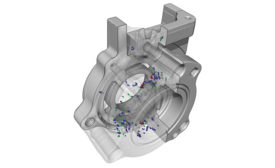

Image Analysis

IMAGE ANALYSIS SOFTWARE HAS BECOME MORE COMPLEX BUT EASIER TO USE

July 8, 2015

Automation

AUTOMATED MACHINE VISION SYSTEMS ARE FASTER, SMARTER AND MORE DETAILED THAN EVER.

March 3, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing