Articles by Ernie Husted

Boom Breaks the Barrier on Enterprise Measurement Solution

It improves quality, increases speed to market, and reduces cost.

February 6, 2020

GD&T, Manufacturing Imperative

Without it, nothing ships, and nobody gets paid.

March 8, 2019

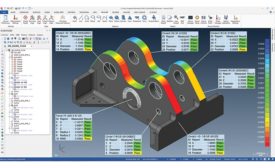

Model-Based Definition Puts GD&T Data to Work

Quality inspection used to be a disparate process isolated in a lab. Today it is much more integrated with the production floor through in-process inspection and open CAD-based measurement software.

March 8, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing