When it comes time to buy a coordinate measuring machine (CMM) or a vision system, fixturing often is overlooked until the equipment is on the floor and parts need to be measured. To avoid delays, fixturing should be addressed while the project still is in the planning stages.

During the past 10 years, CMMs and vision systems have become more sophisticated and less dependent on precision fixturing to present the parts to the inspection equipment. In the past, fixtures were designed and built as if they were gages. At that time, much of the inspection equipment was manually operated and not programmable. Software was not capable of processing the information as it is today. Therefore, fixtures were designed to present the part to the probe head or camera of the inspection equipment, and many times multiple stations were required to access all the features of a part. Fixtures also were designed to position the part to all of its primary datums, leading to complicated fixtures. Today, advances in the machines and software have allowed inspection equipment manufacturers to measure parts better and faster. Correct fixturing is the key to success.

Custom or modular?

Two types of fixturing are used, depending on the application-custom or modular. Modular fixtures are capable of fixturing most parts and presenting parts in the best attitude to the inspection equipment. Custom fixtures are designed and built for a specific application such as high-volume inspection on the shop floor or complex geometry of the part.

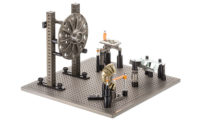

Modular fixtures handle a variety of part materials and shapes. These fixtures start with a base plate that provides for a variety of sizes, depending on the application or the size of the CMM or vision system. Then there are options of fixturing components to elevate, locate and secure a part into position. Adjustable components are available that level or set a part at the desired position to best access it for the necessary measurements.

Components that can be used for securing a part include clamping, magnets or suction cups. Modular fixtures can fixture up parts and provide the flexibility to quickly change over for another part in the future. Some systems use alphanumeric-labeled plates to document and record the fixture setup for other inspection personnel's future use and to create a standard. Some applications may call for multiple modular fixtures to leave the part setups assembled for faster or more recurring inspections. This allows for flexibility for quick changeover if necessary; it also increases the throughput with the inspection equipment to grab a fixture, load the part and bring up the part program on the inspection equipment. It is off and measuring.

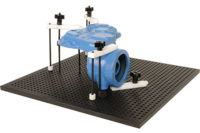

Custom fixtures are best suited for high production or a part with complex geometry. A custom fixture accommodates the part and presents it to the inspection equipment in the best attitude.

Custom fixtures can use different methods for positioning and securing a part in place.

When custom fixtures are needed, it is best to contact a fixture company familiar with CMMs and vision systems. It also is important to have the fixture company's design engineer communicate with the application engineer or inspection technician who will be programming the part to be inspected. This way, not only are the fixturing requirements addressed, the type of probing or back-lighting used to inspect the part also is addressed, thereby limiting the opportunity for rework because of interferences with the inspection equipment and the fixture.

Custom fixtures provide durability for parts inspected daily in high-

production environments. Some applications call for families of parts to be inspected in lots of 10, 25 or even 50 at a time. This allows the inspection equipment to inspect more parts without having to load and unload parts on the inspection equipment. Custom fixtures also are needed when a part's geometry is so complex that the only option is to fixture the part and to inspect it accurately and efficiently. Again, at the start, working with a fixture company and the inspection equipment manufacturers or distributors will help get productivity out of the inspection equipment.

Up front

Many CMM and vision system manufacturers and distributors do not emphasize the need for fixturing up-front with potential buyers. These manufacturers need to explain the importance of fixturing.

In today's world of price reductions and stiff competition, the inspection equipment industry finds it difficult to give a potential customer a complete solution. The initial quoting process should give options for fixturing, probing and possible part programming requirements. When the customer receives quotes and sees that one of the quotes does not list fixturing or other options, the customer is lead to believe that they are not needed.

The customer needs to see all the quotes stated as apples-to-apples, going after the lowest price. To give the lowest price, inspection equipment companies may leave fixturing and other beneficial options off the quote. Although many of these same companies are looking to suppliers for a complete solution, this purchasing process does not allow the sales personnel overseeing the inspection equipment to provide it, so the inspection equipment comes into the facility and will sit without much productivity.

Unless it is a flat-heavy steel part, fixturing is required to allow multiple operators of the inspection equipment, as well as a variety of different parts, to assess the inspection equipment. Whether it is modular or custom fixturing, lack of fixturing will cause the project to fall short of the complete solution. This is why fixturing requirements need to be addressed well before decisions are made.

The potential buyer must decide if applications are best suited for custom or modular fixturing. If it's custom fixturing, enough time must be allocated to discuss requirements, as well as an initial concept with the fixture company and inspection equipment sales and applications personnel. Time then must be allocated for review, changes and the final design, which can take several weeks. Modular fixturing can be put in place on the inspection equipment within days of its arrival. Planning of the fixture requirements is important to the success of the inspection equipment's arrival to the customer's facility. It cannot be something that is pushed away as if the customer will be able to get by without it.

No difference

Fixturing for CMMs or vision systems is no different than fixturing for machining equipment. Fixturing should be the number-two priority, after the equipment itself. Rarely is machining equipment purchased without fixturing for a production application.

Whether purchasing a CMM or vision system, keep in mind the success of the inspection equipment comes faster when fixturing is a priority. Modular or custom fixturing is the key to getting the complete solution. Q